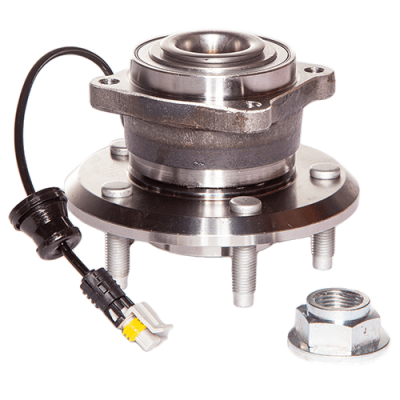

Walhberg’s commitment is to permantly adapt to the international’s market growing technical requirements for improvement. As far as modern-day vehicle engineering is concerned, friction and wear reduction are the keys to staying competitive in the global economy. This is why Walhberg’s patented the cutting edge Nano friction CONTROL TM technology which optimizes performance and guarantees a longer life for the parts.

Our years of scientific research reflected in the Nano friction CONTROLTM technology conduce to significant advantages for the end-user by minimizing friction values (and therefore reducing heat build-up) and increasing wear resistance.

With the rapid development of nanotechnology, our products meet new opportunities: driven by innovation, Wahlberg bearings deliver substantial and immediately measurable performance benefits, with associated cost savings to the automotive industry.

Friction problems at contact interfaces cause mechanical deterioration, damage and short life. This is why reducing it is one of the most critical issues for designers and users, as the economical and technological benefits of controlling friction and wear are tremendous.

The Nano friction CONTROLTM technology offers better mechanical, physical properties and tribological performance than traditional technologies. Its uniqueness relies in the superior performance of the treated components.